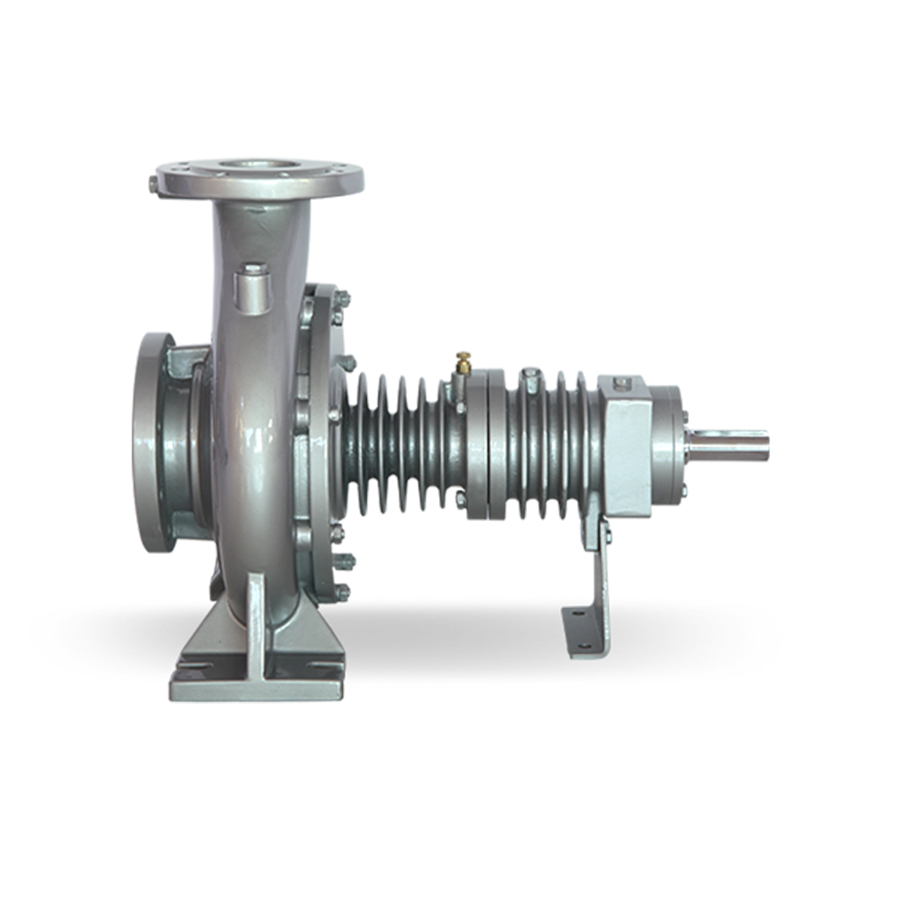

Thermal Oil Pump

Thermal Oil Pump Properties

-Horizontal shaft, volute, single stage, end suction, air cooled, closed impeller centrifugal pumps.

-Suction and discharge flanges conform to EN 1092-2 / PN 16. (flanges for pumps with stainless steel body conform to EN 1092 – 1 / PN 16)

-With the detachable design of the pump, it is possible to remove the bearing assembly, the seal bearing, the pump shaft and the impeller without removing the snail from the pipe. (Optionally, the rotor group of the pump can be removed without removing the motor from the motor carrier by applying the spacer sleeve coupling).

-All impellers are balanced dynamically or statically in accordance with ISO 1940 class 6.3.

-The direction of rotation is clockwise when viewed from the motor side.

-The axial force is compensated by the balancing vanes on the rear of the impeller.

-TCP-K type pumps use “oil lubrication” bearings as standard.

Thermal Oil Pump Technical Data

| Discharge Flange | DN 65 – DN 150 |

| Capacity | up to 500 m³/h |

| Head | up to 100 m |

| Working Temperature | up to 350 ˚C* |

| Casing Pressure (Pmax) | 10 bar (16 bar)* |

Thermal Oil Pump Applications:

-Oil Industry

-Chemial Industry