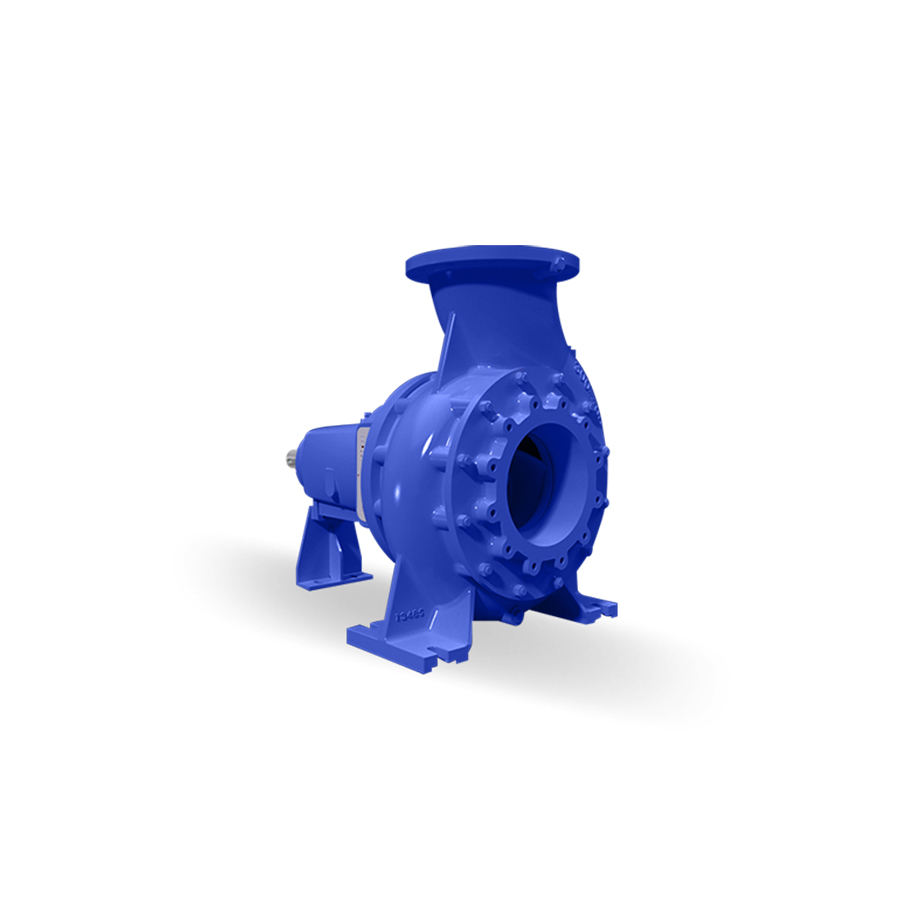

Waste Water and Process Pump

Waste Water and Process Pump Properties

-Horizontal / Vertical, wide volute casing, single stage, end suction, centrifugal pumps with enclosed, semi-open or vortex type impeller.

-18 basic sizes covering wide range of operational area.

-Due to the back-pull-out design, the complete bearing assembly including impeller and casing cover can be dismantled without removing the volute casing from the pipe system. (With spacer coupling application, also possible to take out the rotor group without dismantling the electric motor.)

-Discharge flanges conform to EN 1092-2 / PN 10. (EN 1092-1 / PN 10 for steel or stainless steel casing) •All impellers are balanced dynamically or statically according to ISO 1940 class 6.3.

-Axial thrust is balanced by impeller back ribs.

-Direction of rotation is clockwise viewed from drive end.

-Bearings of TT-DI type pumps are “life time grease lubricated” ball bearing up to TT-DI 150-315 size. For bigger sizes oil lubricated bearings are used. In vertical design (TT-DI-M) always grease lubricated bearings are used.

Waste Water and Process Pump Technical Data

| Discharge Flange | DN 40 – DN 300 |

| Capacity | up to 1600 m3/h |

| Head | up to 95 m |

| Working Temperature | from -10 ⁰C to + 110 ⁰C* |

| Casing Pressure (Pmax) | 10 bar (16 bar)* |

Waste Water and Process Pump Applications:

-Domestic and industrial raw sewage liquid transfer

-Sewage treatment plants

-Liquid transfer containing sludge and solid particles

-Factory waste water drain

-Transfer of viscous liquids and suspensions

-Transfer of liquids in paint plants

-Paper and cellulose industry facilities

-Cooling water systems

-Iron and steel plants