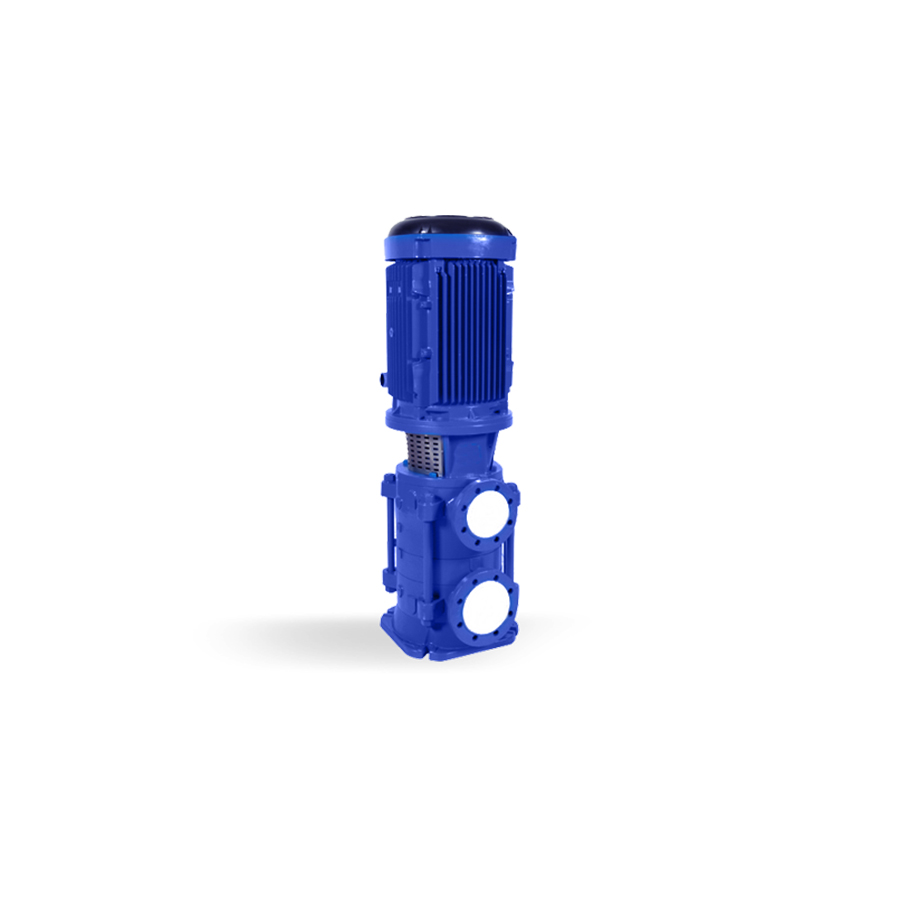

Vertical Multi Stage Pump

Vertical Multi Stage Pump Properties

-Centrifugal pumps with vertical shaft, split body, diffuser, multistage, closed impeller.

-8 models from DN 32 to DN 150 discharge flange diameter.

-Suction flanges according to EN 1092 – 2 / PN 16 and discharge flanges to EN 1092 – 2 / PN 40 (PN 63). (flanges in pumps with stainless steel body material according to EN 1092-1 standard pressure class.)

-TAR-D and TAR-DY pumps are used with high efficiency electric motors according to IEC size.

-Pump and motor shafts are connected to each other with rigid coupling.

-All impellers are balanced dynamically or statically in accordance with ISO 1940 class 6.3.

-Axial force is balanced by impeller balancing holes system.

-The direction of rotation is counterclockwise when viewed from the motor side.

-In TAR-D and TAR-DY type pumps, “grease lubricated” bearings are used as standard. The plain bearings used on the underside of the pumps are lubricated with the pressed liquid.

Vertical Multi Stage Pump Applications:

-Power Plants

-Agricultural Irrigation and Drainage

-Oil Industry

-Building System

-Water Treatment and Pressurization

-Mining

-Chemial Industry

-Heating, Ventilating and Air Conditioning

-Fire Fighting

-Food and Beverage Industry

-Iron and Steel Indusrty